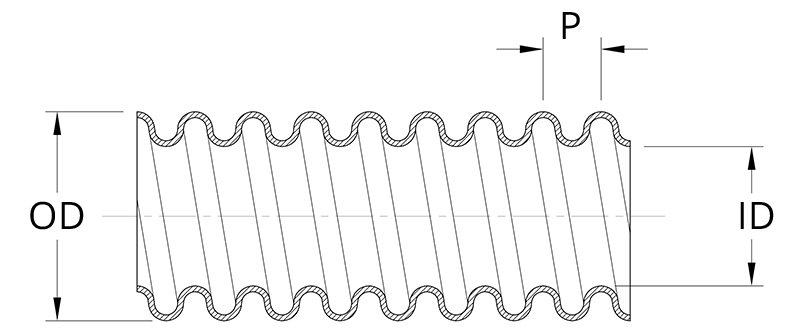

PTFE convoluted tubing is produced using a modified grade of standard PTFE (PolyTetraFluoroEthylene) offering the advantage of excellent flex-life performance compared to most other fluoropolymers together with greatly improved stress crack resistance.

Containing fewer pinhole voids than standard material, PTFE convoluted tubing benefits from much lower permeation making it an excellent choice for the transport of fine chemicals and very ‘searching’ gases such as chlorine.

FDA Compliant

UL94 V-O flammability rating

ADI Free

USP Class VI Compliant

Get in touch with our experienced team to discuss your Fluoroplastic requirements. Simply click the button below to send us a message or call us on +44 (0)1785 859 054.

Get in touch